+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

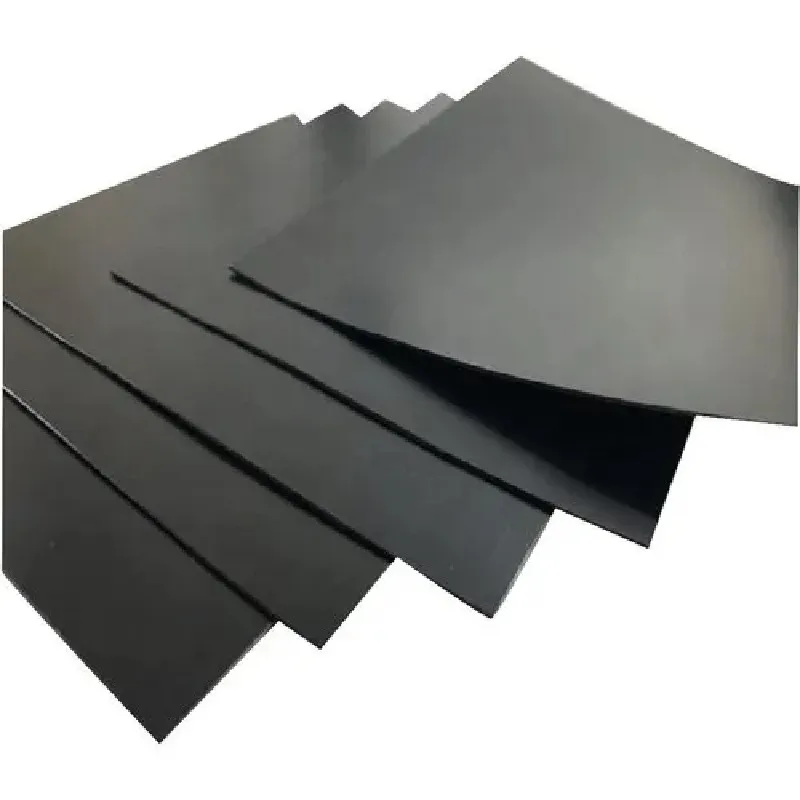

Geomembrana para estanques is a widely adopted geosynthetic solution for lining agricultural ponds, irrigation reservoirs, aquaculture basins, and industrial containment structures, because it provides a continuous, low-permeability barrier that can be engineered for long-term performance when correctly specified and installed. In modern water containment systems, geomembranes are commonly combined with other geosynthetics to form complete lining solutions, such as those described in geosynthetic liner systems.

What is a geomembrana para estanques and how does it work in geosynthetic systems?

A geomembrana para estanques is a polymeric geomembrane used as an impermeable liner to prevent water loss and protect surrounding soil and groundwater. Within geosynthetic systems, it functions as the primary hydraulic barrier, relying on the intrinsic impermeability of polymers such as HDPE, LLDPE, PVC, or EPDM rather than soil compaction. This is why HDPE geomembranes, widely used in reservoirs and ponds, are considered a core product category in modern containment engineering, as explained in HDPE geomembrane applications. Measured permeation rates for polymeric geomembranes are commonly several orders of magnitude lower than those of compacted clay liners, according to Koerner, R.M., Designing with Geosynthetics.

How is the appropriate thickness and material selected for pond applications?

The selection of geomembrane thickness and polymer type is governed by mechanical risk, exposure conditions, and service requirements rather than by pond size alone. Designers evaluate subgrade roughness, puncture risk, slope geometry, settlement potential, and UV exposure to define the appropriate liner specification. In practice, thicker liners and protective layers are often used together with nonwoven geotextiles to reduce puncture risk and extend service life. Industry specifications commonly reference ASTM tensile and durability test methods, with ASTM D6693 issued by ASTM International forming a widely accepted technical benchmark.

Why is installation quality critical to the performance of geomembrane-lined ponds?

In pond and reservoir projects, most leakage issues are traced to installation defects rather than material failure. Proper subgrade preparation, controlled thermal welding, and systematic quality control testing are essential to ensure liner integrity. Professional installation procedures follow recognized QA/QC practices for seam testing and visual inspection, which are standard in large-scale water containment projects. Field experience shows that structured QA/QC programs significantly reduce leakage risk, a principle reinforced in guidelines published by the Geosynthetic Institute (GRI) and reflected in engineered solutions such as geomembrane installation systems.

What service life can be expected from geomembranes used in ponds and reservoirs?

Service life expectations depend on polymer formulation, liner thickness, exposure conditions, and construction quality. Durability is evaluated using accelerated aging and oxidation resistance testing, which supports long-term performance modeling. When geomembranes are adequately protected and installed under controlled conditions, long service lives are achievable. Studies report projected service lives of several decades—often exceeding 50 years—for HDPE geomembranes under favorable conditions, as documented in Koerner, R.M., Designing with Geosynthetics. For this reason, geomembrana para estanques remains a preferred solution for sustainable water storage and management projects.

La geomembrana para estanques es un componente clave dentro de los sistemas geosintéticos modernos, ya que permite lograr una impermeabilización confiable y duradera en reservorios de agua, estanques agrícolas, acuícolas e industriales. Su desempeño no depende únicamente del material, sino del diseño integral del sistema, que incluye la correcta selección del polímero y el espesor, una adecuada preparación de la subrasante, el uso de capas de protección y una instalación con control de calidad riguroso. Cuando estos factores se gestionan correctamente, la geomembrana ofrece una solución eficiente, segura y de larga vida útil, contribuyendo a una gestión sostenible del agua y a la protección del entorno.

Obtenga una muestra gratis

We’ll respond as soon as possible(within 12 hours)